Automotive brake systems are essential for vehicle control and safety. A comprehensive understanding of their functionality, especially the master cylinder, is critical for both seasoned car enthusiasts and everyday drivers. This article delves into various aspects of brake systems, including the types of systems, master cylinder anatomy, common brake failure mechanisms, and effective maintenance methods. Moreover, it offers insights into AMSOIL’s approach to fluid formulation and emphasizes the broader importance of peace of mind in brake maintenance.

Types of Brake Systems

Since 1967, automotive brake systems have evolved significantly. Two primary types of brake systems are used in vehicles today: the longitudinally split system and the diagonally split system.

Longitudinally Split System

In a longitudinally split brake system, the front wheels are controlled by one system, while the rear wheels are managed by another. This configuration ensures that if a failure occurs in one section, the other section remains functional, thereby providing a level of redundancy and safety.

Diagonally Split System

The diagonally split system pairs the right front wheel with the left rear wheel and the left front wheel with the right rear wheel. This design ensures balanced braking effort and better control if one section of the system fails. Ensuring any brake system, whether longitudinally or diagonally split, operates optimally requires a thorough understanding of the master cylinder, the heart of the brake system.

Master Cylinder Anatomy

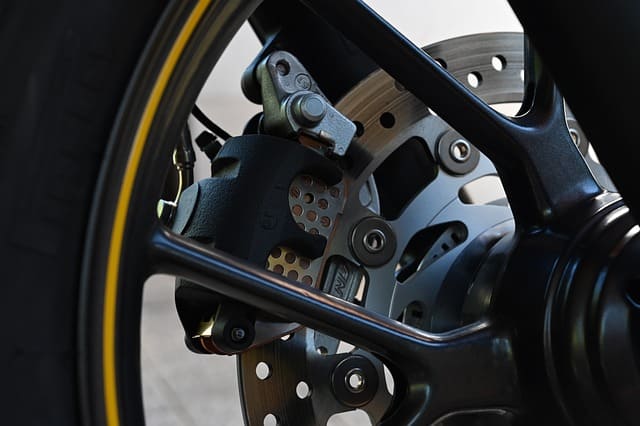

The master cylinder is a pivotal component in automotive brake systems. It converts the driver’s pedal input into hydraulic pressure, ensuring the effective transmission of force to the brake calipers or wheel cylinders.

Two Chambers in the Master Cylinder

The master cylinder contains two distinct chambers: the high pressure chamber and the low pressure chamber. Understanding these chambers is crucial to diagnosing and addressing brake issues.

High Pressure Chamber

This section of the master cylinder is responsible for generating the hydraulic pressure necessary to engage the brakes. When the driver presses the brake pedal, the primary piston compresses the brake fluid within this chamber.

Low Pressure Chamber

The low pressure chamber acts as a reservoir, accommodating any excess brake fluid and helping maintain pressure within the system. Any transfer of fluids between the high and low pressure chambers can indicate a malfunction.

Components of the Master Cylinder

Several key components are housed within the master cylinder, each playing a vital role in its functionality.

Primary Piston

The primary piston is the first point of contact when the brake pedal is pressed. It moves within the high pressure chamber to generate the necessary hydraulic force.

Secondary Piston

The secondary piston acts in tandem with the primary piston, ensuring balanced pressure distribution and effective braking performance.

Primary Seal

The primary seal ensures the integrity of the high pressure chamber. It prevents brake fluid from leaking out, maintaining the necessary pressure for effective braking.

Secondary Seal

Similarly, the secondary seal prevents fluid from leaking between the secondary piston and the chambers it interacts with, ensuring efficient fluid transfer.

Brake Failure Mechanism

One common issue in brake systems is the brake pedal slowly going to the floor. This phenomenon is often caused by a failure within the master cylinder, typically involving the primary seals.

Explanation of Pedal Slowly Going to the Floor

When the brake pedal starts sinking to the floor, it usually indicates that the high pressure chamber is losing pressure. This loss can be traced to faulty seals within the master cylinder.

Pressure Bleeding from High to Low Pressure Chamber

A failing primary seal allows brake fluid to bleed from the high pressure chamber into the low pressure chamber. This leakage results in a loss of hydraulic pressure, causing the brake pedal to slowly sink when pressed.

Role of Primary Seals in Brake Failure

The primary seals are crucial for maintaining the integrity and pressure within the high pressure chamber. Any degradation or failure of these seals directly impacts brake performance, necessitating timely intervention and maintenance.

Addressing Brake Issues

Addressing brake problems promptly is essential to ensure vehicle safety. One crucial aspect of brake maintenance involves replacing the brake master cylinder and flushing the brake system.

Replacing the Brake Master Cylinder

When the master cylinder’s seals fail, replacing the entire unit is often necessary. This process involves:

- Removing the old master cylinder: Carefully disconnect the brake lines and mounting bolts.

- Installing the new master cylinder: Secure the new unit in place and reconnect the brake lines.

Flushing the Brake System

Flushing the brake system removes any contaminants and air bubbles, ensuring optimal brake performance. This step is vital after replacing the master cylinder.

Bench Bleeding Technique

Ensuring the master cylinder is free from air bubbles before installation is critical. The technique to achieve this is known as bench bleeding.

Importance of Bench Bleeding

Bench bleeding removes any trapped air within the master cylinder, which can otherwise cause spongy brake pedal feel and inefficient braking.

Step-by-Step Process

Attaching Lines to Master Cylinder

- Secure the master cylinder in a vise: Ensure it is stable and level.

- Attach bleed tubes: Connect tubes from the outlet ports back into the reservoir.

Pushing In and Out on the Cylinder

- Push the piston repeatedly: Use a tool to slowly push the piston in and out, forcing air bubbles out of the hydraulic system.

- Observe fluid movement: Continue this process until no air bubbles are seen in the fluid.

Purpose: Removing Bubbles from Chambers

The primary goal of bench bleeding is to ensure that the high and low pressure chambers within the master cylinder are free from air bubbles, which can compromise braking efficiency.

Continuing Until All Bubbles are Gone

Persist with the bench bleeding process until the fluid flowing through the bleed tubes is clear of air bubbles. This ensures that the master cylinder is primed and ready for installation.

AMSOIL’s Approach to Fluid Formulation

AMSOIL’s commitment to innovation and quality is evident in their approach to fluid formulation. They meticulously adjust their products to meet the specific needs of various automotive components.

Focus on Equipment Needs

AMSOIL’s formulation strategy begins with an in-depth understanding of the equipment’s requirements. This includes evaluating the unique demands of different vehicles and their components.

Adjusting Formulary to Suit Specific Requirements

By tailoring their products to meet specific needs, AMSOIL ensures optimal performance and longevity. This adaptive approach sets them apart in the automotive industry.

Product-Specific Considerations

Different automotive applications require tailored solutions. AMSOIL addresses these diverse needs through their specialized product formulations.

Fuel Additives

Addressing Deposit Issues

Fuel additives are designed to combat deposit build-up within the fuel system, ensuring efficient combustion and engine performance.

Engine Oils

Adapting to Specific Engine Types

Engine oils are formulated to meet the unique demands of various engines, whether in passenger vehicles, trucks, or motorcycles. This includes considerations for temperature, load, and component wear.

Motorcycle Oils

Consideration for Clutch Performance

Motorcycle oils must also account for clutch performance, ensuring seamless power transfer and longevity of components.

AMSOIL’s Testing Process

AMSOIL’s rigorous testing process underscores their commitment to quality and reliability.

Building Engines for Testing

They build engines specifically for testing purposes, allowing them to simulate real-world conditions and evaluate product performance.

Rigorous Testing Procedures

AMSOIL subjects their products to stringent testing protocols, far exceeding the typical use cases of everyday drivers. This ensures their products perform reliably under extreme conditions.

Putting Products in Extreme Situations

By testing their oils and additives in harsh environments, AMSOIL guarantees their products can withstand the most demanding conditions, providing peace of mind to their customers.

Importance of Peace of Mind in Brake Maintenance

Maintaining your brakes ensures not only your safety but also that of your passengers and other road users. Proper maintenance and high-quality fluids are essential for optimal brake performance.

Emphasizing the Role of Proper Brake Fluid

The right brake fluid, free from contaminants and air bubbles, is crucial for efficient braking. Regular maintenance and the use of quality products can significantly impact your vehicle’s safety and performance.

Accessing AMSOIL Products

For those seeking peace of mind in brake maintenance and overall vehicle performance, AMSOIL offers a range of high-quality products tailored to meet your needs. Visit bestengineoilintheworld.com for more information and to explore their extensive product lineup, ensuring your vehicle remains in top condition.

Proper brake maintenance is crucial for the safety and performance of your vehicle. By understanding the intricacies of your brake system, including whether you can bleed brakes from the master cylinder, you can ensure your brakes function effectively, providing peace of mind on every journey.