Did you know that a thin layer of oil is all that stands between your engine’s metal components and catastrophic damage? Understanding the critical role of motor oil is essential for any vehicle owner. Synthetic oils, thanks to their advanced formulation, outperform conventional oils by providing better wear protection, enhancing engine cleanliness, and improving fuel efficiency. With motor oil lab tests backing their effectiveness, AMSOIL synthetic oils ensure your engine runs smoothly and lasts longer. Stick around to find out why making the switch to synthetic oil could be the best decision for your vehicle’s health.

The First in Synthetics®: Why Motor Oil Quality Matters

You often hear us proudly mention that AMSOIL was the first synthetic motor oil to meet API standards, but what does that really mean, and why should you care? It’s essential to understand that there are organizations around the globe, such as the American Petroleum Institute (API), that dedicate their efforts to ensuring that lubricants uphold stringent quality metrics. These standards aren’t arbitrary; they’re meticulously crafted to meet the demanding requirements of various vehicles, machines, and equipment under diverse operating conditions. By meeting API standards, AMSOIL guarantees a level of reliability and performance that protects engines and enhances their longevity. This commitment to quality means fewer breakdowns and more consistent operation, which ultimately benefits consumers and professionals alike in terms of cost savings and efficiency.

Common Motor Oil Testing Standards Explained for Beginners

The American Petroleum Institute (API), established in 1919, develops standards aimed at enhancing the safety, efficiency, and sustainability of equipment used in the petroleum, natural gas, and petrochemical industries. These standards cover a wide array of equipment and operational procedures to ensure industry practices meet stringent safety and environmental benchmarks. Similarly, the International Lubricant Specification Advisory Committee (ILSAC), comprising numerous automobile manufacturers, formulates performance standards for engine oils specifically designed for gasoline-powered passenger vehicles. These standards ensure that the engine oils provide the necessary protection and efficiency for modern engines, thereby contributing to the longevity and performance of vehicles. In parallel, the European Automobile Manufacturers’ Association (ACEA) includes 16 major vehicle manufacturers who collaboratively set engine oil specifications across Europe. This group focuses on harmonizing standards to improve engine performance and reduce emissions, addressing specific environmental concerns pertinent to the European market. Collectively, these organizations play a pivotal role in standardizing practices and improving technological advancements within their respective domains, directly impacting the automotive and energy sectors.

Since 1905, the Society of Automotive Engineers (SAE) has played a crucial role in creating and disseminating standards for all aspects of motor vehicles. By establishing these detailed guidelines, the SAE ensures that engineers are equipped with the knowledge and skills essential for developing safer, cleaner, and more accessible transportation solutions. Through rigorous training programs and workshops, the SAE fosters a culture of continuous improvement and innovation within the automotive industry.

The American Society for Testing and Materials (ASTM) is a prominent global organization responsible for setting technical standards across a wide array of materials, products, systems, and services. Through meticulous testing procedures and quality benchmarks, ASTM provides the foundation for consistency and reliability within numerous industries.

In its commitment to upholding high standards, the SAE employs specific ASTM tests to verify that lubricants perform effectively under various vehicular conditions. By integrating these rigorous ASTM evaluations, the SAE ensures that each lubricant not only meets but often exceeds the necessary performance criteria, thus enhancing vehicle reliability and longevity. This collaboration between SAE and ASTM underscores the importance of standardization and quality assurance in advancing automotive technology.

As mechanical technology progresses, lubrication requirements evolve to meet new challenges and specifications. Following the guidelines established by authoritative organizations ensures that lubricants meet the rigorous standards set by original equipment manufacturers (OEM). This adherence not only guarantees optimal engine performance but also plays a critical role in preventing potential damage that could arise from substandard lubrication. Without these standardized specifications and rigorous testing procedures, the quality of aftermarket lubricant products could drastically diminish, posing significant risks to engine health, operational efficiency, and overall safety.

Consider the stringent testing that OEM guidelines require, which includes assessments of viscosity, thermal stability, and wear resistance, among other factors. These tests simulate real-world operating conditions to ensure that lubricants can withstand extreme environments and prolonged use. By complying with these standards, lubricant manufacturers provide a level of assurance that their products will perform reliably, thus maintaining the integrity and longevity of mechanical systems.

Moreover, these guidelines serve as a crucial benchmark for quality, setting a high standard that aftermarket products must meet to be deemed safe and effective. Non-compliance with these standards could lead to a host of issues, such as increased engine wear, overheating, and even catastrophic failure. Given the complexity and precision of modern mechanical systems, using inferior lubricants could significantly shorten their lifespan and increase maintenance costs.

It’s also worth noting that some may argue that aftermarket lubricants can offer similar performance at a lower cost. However, without adhering to OEM guidelines, there’s no guarantee of consistent quality and performance, making this a risky proposition. Ultimately, the guidelines established by authoritative organizations are essential for ensuring that lubricants not only meet but exceed the demands of today’s advanced mechanical systems, providing peace of mind to both manufacturers and users alike.

Top Methods for Motor Oil Testing

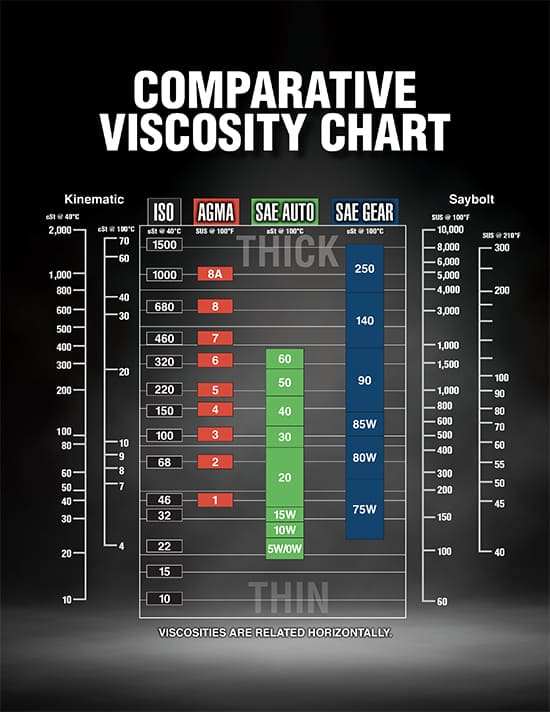

Understanding common tests necessary for motor oil certification is crucial for ensuring engine performance and longevity. ASTM D2270 evaluates the viscosity index, a vital parameter that measures how much the motor oil’s kinematic viscosity changes between ambient (40°C) and operating (100°C) temperatures. A higher viscosity index signifies that the oil’s viscosity decreases less as the temperature rises, maintaining its protective qualities more effectively at higher operating conditions. This consistency is essential because it ensures optimal lubrication, minimizing wear and tear on engine components, which can lead to costly repairs and reduced engine life.

Additionally, ASTM D445 is used to determine the actual viscosity at both ambient (40°C) and operating (100°C) temperatures. This test is critical for confirming that the oil meets the specific viscosity grades required for different engine types. Proper viscosity is essential for ensuring the oil flows correctly, providing adequate protection under varying conditions. Without meeting these standards, an oil might fail to lubricate the engine properly, leading to increased friction, overheating, and ultimately, engine damage. These tests collectively ensure that the motor oil can perform reliably in real-world driving conditions, safeguarding the engine’s integrity and efficiency.

Heated oil carries an additional risk of losing its viscosity under pressure conditions. The ASTM D5481 (HTHS) standard method evaluates viscosity at both high temperatures and pressures that closely mimic those found within an engine. Subjecting oil to these pressures reveals viscometric properties that aren’t detectable with other standard viscosity tests. Engine oil additives often modify flow characteristics, making it crucial to examine these properties under real-world conditions. Without such evaluation, you might miss critical information about how the oil will perform when the engine is operating under sustained high stress. For instance, additives designed to enhance lubricity might behave differently under extreme heat and pressure, potentially leading to breakdown or reduced effectiveness. This kind of detailed analysis ensures the oil maintains its performance and protects engine components effectively. Regular viscosity tests don’t account for these dynamic conditions, which makes the high-temperature, high-shear testing indispensable for accurate assessment. This thorough approach not only extends engine life but also optimizes fuel efficiency by ensuring consistent lubrication under demanding conditions.

Maintaining the proper viscosity of oil in extreme heat and ensuring it stays fluid in extreme cold is crucial for optimal engine performance. The ASTM D97 test measures the pour point, determining the lowest temperature at which the lubricant can still flow. This is vital for ensuring that the oil can perform well in freezing conditions, preventing engine wear and failure. Similarly, the ASTM D5293 (CCS) test simulates the viscosity of engine oil during cold engine cranking. By verifying that the oil remains fluid enough to start an engine at specified low temperatures, this test ensures engines can start reliably and run smoothly even in bitterly cold weather.

Consider a scenario where oil fails these tests; engines would struggle to start in winter, leading to increased wear and potential damage. Ensuring these properties aren’t just about performance but also about extending engine life and preventing costly repairs. Thus, maintaining proper oil viscosity across temperatures ensures engines operate efficiently and start reliably, regardless of harsh environmental conditions. This comprehensive approach ultimately safeguards the engine against varied temperature extremes, ensuring long-term durability and performance.

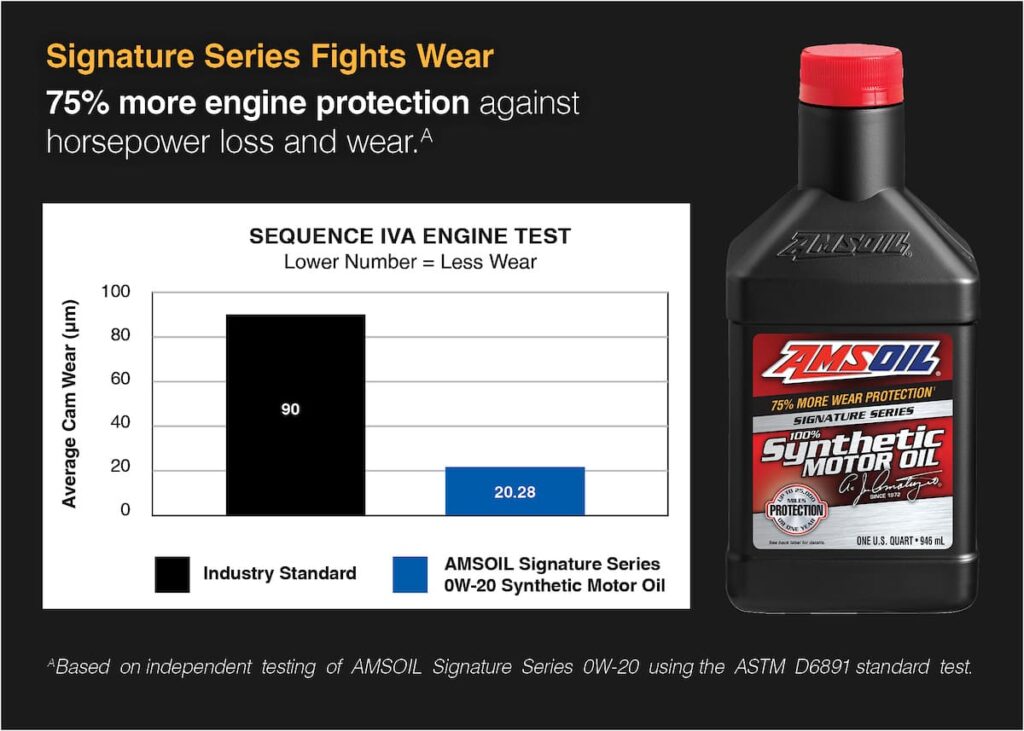

The primary function of oil is to reduce wear resulting from metal surfaces rubbing against each other. This wear reduction is essential for extending the lifespan of machinery components, which is critical for maintaining efficient operation and reducing maintenance costs. To evaluate the effectiveness of lubricating oils in minimizing wear, the ASTM D4172 test, commonly known as the four-ball wear test, is utilized. This standardized test assesses the oil’s performance in preventing wear during sliding contact scenarios by measuring the scar diameter on steel balls under controlled conditions.

Precise data from the scar diameter measurements offer detailed insights into the oil’s wear prevention capabilities. Additionally, another crucial aspect of lubricant performance is its ability to neutralize acidic compounds, which is measured using the ASTM D2896 test. This test determines the Total Base Number (TBN) of the oil. A higher TBN signifies a greater ability to suspend wear-inducing contaminants and mitigate the long-term corrosive effects of acids.

This characteristic is particularly important in applications where oils are exposed to harsh chemical environments. By effectively neutralizing acids, oils with a higher TBN not only extend the useful life of the lubricant itself but also protect the machinery from acid-induced wear and corrosion. Consequently, selecting oils with a high TBN is fundamental for enhancing the durability and reliability of both the lubricant and the equipment it safeguards.

Understand and Appreciate AMSOIL’s Commitment

By understanding why motor oil lab tests are so critical, you can truly appreciate AMSOIL’s commitment to providing detailed data sheets. These reports are not just technical jargon; they are evidence of AMSOIL’s superior performance. Whether dealing with extreme temperatures or heavy loads, AMSOIL products not only meet but often exceed industry standards. This proactive approach ensures that you are safeguarding your engine and investment.