Reusing the same filter multiple times is highly discouraged due to the primary function of the filter, which is to effectively capture impurities and retain them within the filter media. As the filter operates over time, it tends to accumulate a variety of contaminants such as dirt particles, soot, metal fragments, and other debris, leading to congestion within the filter media. This congestion can trigger the bypass valve in response to pressure differentials, allowing oil to bypass the filter and prevent oil starvation in the engine. While using contaminated oil as a temporary measure is better than running the engine without any oil, it remains an unreliable long-term strategy. So, can you use the same oil filter twice? It is more cost-effective and prudent to routinely replace the filter at every oil change to safeguard the engine’s optimal functioning and longevity.

Maximizing Engine Performance: Conventional or Synthetic Filters?

When making the decision between a conventional or synthetic filter, it is advisable to choose one crafted with synthetic media for superior protection. Synthetic oil filters offer numerous benefits:

Increased Capacity: Capacity denotes the amount of contaminants a filter can hold while effectively functioning. Although there is no standardized capacity measurement in the industry, full synthetic media boasts greater capacity than conventional media. This heightened capacity is attributed to the smaller fibers in synthetic media, providing more room for contaminants to accumulate without hindering oil flow.

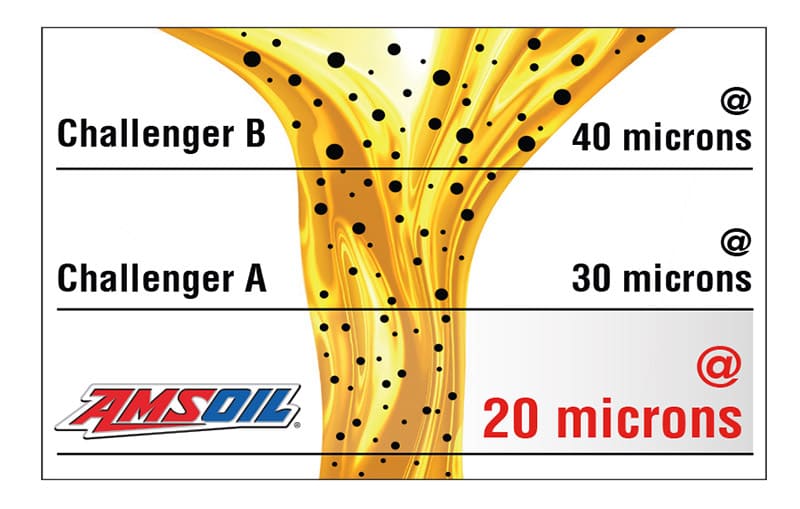

Enhanced Efficiency: Efficiency is a critical factor that denotes the filter’s capability to capture contaminants. Typically, the filter’s efficiency rating is visibly indicated on the packaging or the manufacturer’s official website. This rating is typically represented as a percentage alongside a micron rating. For example, “99 percent at 20 microns,” as evident in AMSOIL Oil Filters. This percentage signifies the contaminants of 20 microns and larger that the filter captures during standardized industry testing (ASTM D4548-12). The higher the percentage, the greater the efficiency.

Improved Durability: Hot oil temperatures can deteriorate the resins binding specific filter media together. Additionally, extreme temperatures may harm the anti-drain valve and baseplate gasket. To counteract this issue, selecting a filter with media reinforcement like a wire backing can enhance durability, enabling it to endure high heat levels and prolonged drain intervals. Opt for an anti-drain valve composed of silicone for optimal durability, ensuring that the oil remains within the filter post-engine shutdown to prevent dry starts the next day.

Unraveling the Mysteries: What’s Really Inside an Oil Filter?

The components found in an oil filter play vital roles in maintaining the engine’s health. First and foremost, the filter media is the cornerstone of the filter, responsible for capturing contaminants that could otherwise harm the engine’s performance. Think of it as the shield that safeguards the engine from impurities, ensuring its smooth operation. Secondly, the gasket may seem like a small detail, but its strategic position on the outer edge of the filter is critical. By creating a secure seal with the engine block, the gasket effectively prevents any oil leaks, promoting optimal functionality. Lastly, the anti-drain valve acts as a gatekeeper, retaining oil within the filter during engine downtime. This ingenious mechanism guarantees swift oil pressure buildup when the engine roars back to life, facilitating a seamless start-up process. Each of these components works harmoniously to uphold the engine’s efficiency and longevity, underscoring the importance of a well-maintained oil filter.

Avoid Engine Damage: When to Replace Your Oil Filter

The lifespan of filters is determined by the quality of the filter and the conditions in which you drive. Lesser-quality inexpensive conventional filters lack the efficiency of filters made with synthetic media. As a result, they accumulate contaminants more rapidly, necessitating more frequent replacements. Particularly, if you drive in dusty or dirty environments, your engine becomes susceptible to higher levels of airborne dirt particles that can infiltrate the engine. This risk increases if the air filter hasn’t been changed for an extended period or if there’s a leak in the intake system.

Moreover, in diesel engines, soot particles have the potential to clump together, forming larger impurities that can become trapped in the filter, exacerbating the issue. This accumulation of contaminants places additional strain on the filter, leading to quicker clogging.

Furthermore, modern direct-fuel-injection vehicles may encounter heightened fuel dilution, further burdening the filtration system. To ensure optimal performance and longevity of your filter, it is vital to adhere to the maintenance guidelines provided by the manufacturer. In cases where specific instructions are not available, following the recommendations outlined in your vehicle’s owner’s manual is advisable.

Reducing Dry Start Risk: Benefits of Pre-Filling Oil Filters [Must-Read]

To mitigate the risk of starting the engine without sufficient oil, it is advisable to pre-fill the filter if possible. Although horizontally oriented filters may present challenges, they too can be pre-filled with oil. A common practice is to pour a small amount of oil into the filter, tilt it sideways to check the oil level, and add more oil if there is room before it starts spilling out of the filter opening. It is crucial to consider that engine manufacturers recommend using 0W-XX or 5W-XX motor oils to ensure easy oil flow during startup, especially in cold conditions. By doing so, the engine is safeguarded against operating without necessary lubrication while waiting for oil pressure to build up. Despite some filter manufacturers arguing against the necessity of pre-filling, it is essential to recognize that their specialization lies in filter production rather than engine functionality. The internet offers conflicting opinions on this matter, with some advocating for pre-filling while others oppose it. Many seasoned individuals who have serviced high-mileage vehicles develop preferences based on their experiences with conversion vans or pickups. Ultimately, the decision on whether to pre-fill the filter should prioritize the engine’s longevity and efficiency.

The Surprising Truth About Mixing Synthetic Oil and Conventional Filters

When considering the compatibility of synthetic oil and conventional filters, it is crucial to understand that although using synthetic oil with a conventional filter or vice versa does not pose safety risks, there are certain factors to consider. One of the key considerations is the extension of drain intervals when utilizing synthetic oil, which can present challenges when paired with a conventional filter. In such cases, the conventional filter may lack the durability required to withstand the extended drain interval, potentially leading to the need for a mid-interval replacement, causing inconvenience to the vehicle owner.

To offer a solution to this concern, AMSOIL has developed meticulously engineered Oil Filters that are specifically designed to address this issue. These filters are built to withstand up to 25,000 miles between changes, aligning perfectly with the recommended drain interval for their Signature Series Synthetic Motor Oil. Particularly noteworthy are the filters with the product code EA15K, which can deliver an impressive 15,000 miles of reliable performance before requiring replacement. This level of durability provides peace of mind to vehicle owners, ensuring that their engines are protected and performing optimally throughout the extended drain interval.

Forgotten Oil Filter Change? Here’s What You Need to Know

If inadvertently forgotten, the replacement of the oil filter can be carried out even after the initial oil change has taken place. To rectify this oversight, simply proceed by swapping out the filter in the customary manner. After installing the new filter, it is recommended to initiate the engine for a brief period to facilitate optimal oil circulation. Subsequently, the engine should be switched off, allowing a short interval for the oil to properly settle within the sump. Following this step, it is crucial to assess the oil level, ensuring it aligns with the manufacturer’s specifications. If required, additional oil should be added to compensate for the portion displaced during the removal of the old filter.

In conclusion, while the question “can you use the same oil filter twice” might cross your mind, it’s crucial to prioritize your engine’s health. Routinely replacing the oil filter at every oil change is a cost-effective strategy that ensures optimal performance and engine longevity. Skimping on this maintenance could lead to significant issues down the road.