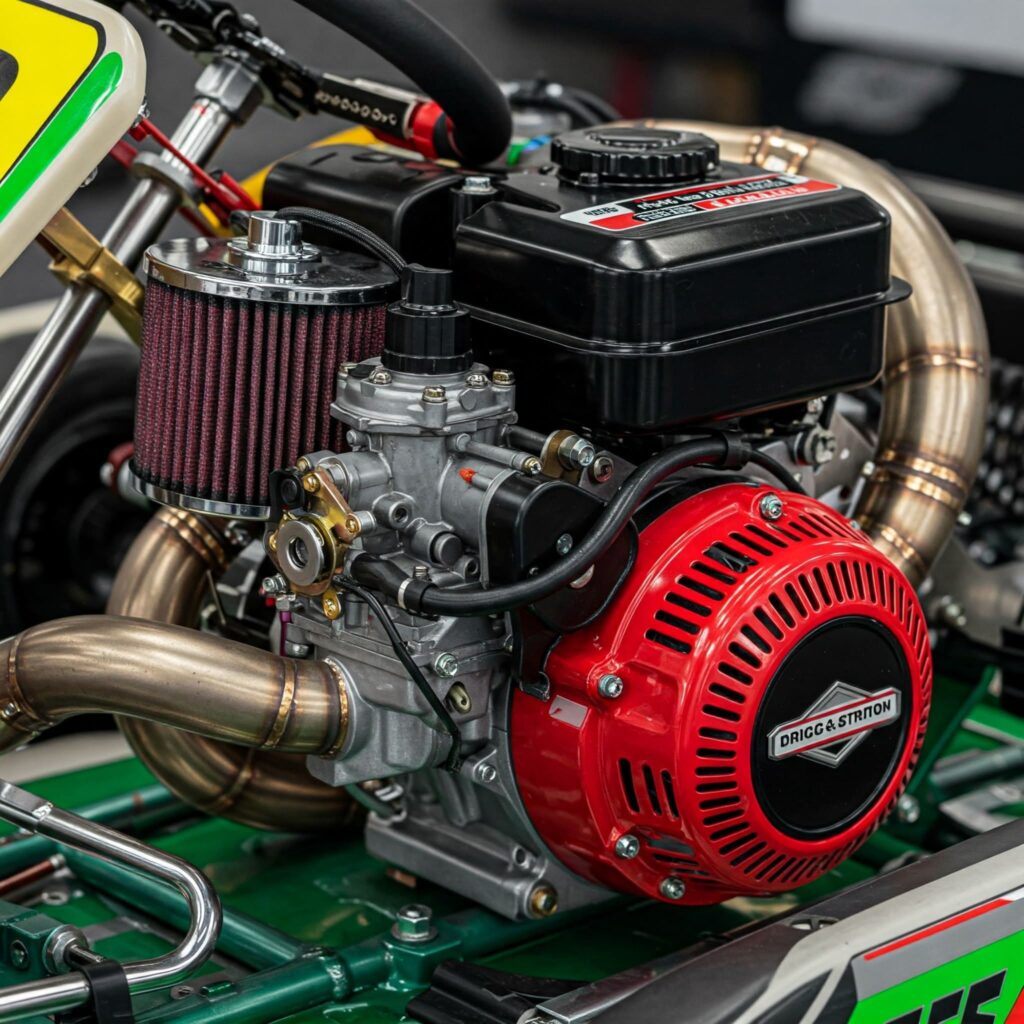

The Briggs & Stratton racing engine—a cornerstone of entry-level motorsports—offers a unique blend of simplicity, affordability, and potential for high-performance tuning. Mastering its operation and maintenance is crucial for competitive success. This article delves into the inner workings of the B&S racing engine, emphasizing critical lubrication practices and maintenance strategies to maximize its potential on the track.

Understanding the Four-Stroke Cycle in Detail

The Briggs & Stratton racing engine operates on the four-stroke cycle, a sequence of events that converts fuel into mechanical power. Each stage requires precise timing and contributes to overall engine performance:

- Intake Stroke: As the piston descends, it creates a vacuum, drawing the air-fuel mixture through the carburetor and into the cylinder. Precise valve timing, often adjusted by experienced tuners, optimizes the volumetric efficiency of this process, ensuring maximum cylinder fill.

- Compression Stroke: With both valves closed, the piston ascends, compressing the air-fuel mixture. The compression ratio—typically around 8:1 in stock engines—determines the amount of energy stored in the mixture. Modified engines often feature higher compression ratios for increased power output.

- Combustion Stroke: Near the top of the compression stroke, the spark plug ignites the compressed mixture, causing a rapid expansion of gases. This forces the piston downward, delivering power to the crankshaft. The timing of the spark ignition is critical and can be adjusted to optimize combustion efficiency.

- Exhaust Stroke: As the piston rises again, the exhaust valve opens, allowing the spent gases to be expelled from the cylinder. Efficient exhaust scavenging is crucial for clearing the cylinder and preparing it for the next intake stroke.

The Critical Role of Lubrication in Racing Engine Performance

Lubrication is paramount in the high-stress environment of racing. It ensures the longevity and performance of key engine components. Here’s a detailed look at the lubrication system and best practices:

- Components Requiring Lubrication: The crankshaft, connecting rod bearings, piston, and cylinder walls all require a consistent supply of clean oil to minimize friction and wear.

- Oil Types: Synthetic oils, with their superior thermal stability and film strength, provide enhanced protection compared to mineral oils. The right viscosity is crucial; too thin, and the oil may fail to protect under high loads; too thick, and it can increase internal friction, reducing power output.

- Cooling Properties: Oil also plays a role in cooling the engine by dissipating heat from the piston and cylinder walls. Synthetic oils generally offer better heat transfer capabilities, reducing the risk of overheating.

- Additives: Many racing oils contain additives that enhance their lubricating properties, such as anti-wear agents, detergents, and corrosion inhibitors.

Maintaining an Unbiased Approach to Lubrication Choices

While synthetic oils generally offer superior performance in racing applications, certain mineral oils with specialized additives can also provide adequate protection for less demanding scenarios. The choice depends on factors such as budget, racing frequency, and engine modification levels. Always consult engine manufacturer recommendations and consider the specific demands of your racing environment.

Essential Maintenance Strategies for Peak Performance

Proper maintenance is crucial for ensuring the reliable performance of your Briggs & Stratton racing engine. Here are some actionable maintenance tips:

- Regular Oil Changes: Oil should be changed frequently, typically every 2-5 hours of racing, depending on the severity of operating conditions.

- Air Filter Cleaning: A clean air filter is essential for preventing dirt and debris from entering the engine. Clean or replace the filter after each race day.

- Spark Plug Inspection: Inspect the spark plug regularly for signs of wear or fouling. Replace it if necessary to maintain optimal ignition.

- Valve Adjustments: Valve lash should be checked and adjusted periodically to ensure proper valve timing.

- Engine Storage: When storing the engine, drain the fuel and add a fuel stabilizer to prevent fuel degradation. Store the engine in a clean, dry environment.

Diagnosing Common Engine Problems Through Inspection and Analysis

Regular inspection and analysis can help you identify potential engine problems before they lead to catastrophic failure. Here are some diagnostic tips:

- Oil Analysis: Regular oil analysis can provide valuable insights into the health of your engine. By monitoring wear metal content, viscosity changes, and the presence of contaminants, you can identify potential problems before they escalate.

- Visual Inspection: Inspect the engine for signs of leaks, cracks, or other damage. Pay close attention to the cylinder head, valve cover, and oil pan.

- Compression Testing: A compression test can help you assess the condition of the piston rings and valves. Low compression can indicate wear or damage to these components.

- Leak-Down Testing: A leak-down test can help you pinpoint the source of compression leaks, such as leaky valves or worn piston rings.

For more insights on common mistakes and preventative measures with the Briggs & Stratton 206 engine, you can find a helpful guide Here.

Achieving Racing Success Through Knowledge and Diligence

Mastering the Briggs & Stratton racing engine requires a blend of technical knowledge, diligent maintenance, and a commitment to continuous improvement. By understanding the engine’s inner workings, selecting the right lubricants, and adhering to rigorous maintenance practices, you can unlock its full potential and achieve competitive success on the track. Four-stroke engine care is an ongoing process that rewards attention to detail and a proactive approach to maintenance.

Whether you’re a seasoned racer or just starting out, a solid understanding of the engine and a commitment to proper maintenance are essential for achieving your goals. By following the guidelines outlined in this article, you can ensure that your Briggs & Stratton racing engine delivers reliable performance and maximizes your chances of success on the track. For more details on high-performance motor oils, explore: Royal Purple Here, Red Line Oil Here, and AMSOIL Here.