— Film Strength, Detergency, Endurance —

When winter drops its hammer, every weak link shows itself. Engines tighten, batteries fade, and oil turns sluggish just when it’s needed most. Snowmobile engines live in that thin margin between mechanical grace and metal fatigue — and the oil you feed them decides which side of that line you end up on.

This isn’t about brands or bottles; it’s about chemistry and consequence. The goal is simple: understand what separates a good two-stroke oil from a great one, and why those differences matter when the thermometer falls off the scale.

Why synthetic oil matters starts at the molecular level. Conventional base oils are made from naturally occurring hydrocarbons that vary in size and shape, leaving behind impurities and weak molecular links. Those irregularities limit how well the oil resists heat, shear, and oxidation once the workload increases.

Synthetic oils, by contrast, are built molecule by molecule for uniformity. That engineered structure gives them stronger film stability, cleaner burn characteristics, and greater resistance to breakdown under extreme heat or cold. The result is simple: less wear, longer service life, and more consistent protection across every moving surface.

Engine protection comes down to physics, not promises. Inside any engine, metal never truly stops fighting metal — it’s only separated by a microscopic oil film that lives or dies by its chemistry. When that film breaks, friction wins instantly, and the cost shows up in wear metals and rebuild bills.

A durable oil isn’t defined by branding; it’s defined by how long that film holds under load, heat, and starvation. High-stability base oils and balanced additives keep the barrier intact when conditions go brutal — when the thin line between lubrication and metal contact decides how long the engine lives.

Cold starts test every weakness in an oil. When temperatures drop, conventional lubricants thicken like syrup, moving sluggishly through the pump and leaving bearings and rings exposed for those first critical seconds. Every turn of the crank under that delay grinds away at protection the engine will never get back.

“Oil that moves like honey at -20 °F is a liability — it might look fine in the bottle, but it won’t flow fast enough to save metal when it counts.”

Synthetic oils stay mobile when the thermometer dives. Their uniform molecular structure flows fast enough to reach hard-to-wet surfaces before scuffing begins, cutting startup wear and stabilizing idle even in sub-zero conditions. High-viscosity-index synthetics—typically around 170 or higher—resist thickening when cold and thinning when hot, keeping injection systems fed evenly below zero.

These cold-flow properties link directly to pour point and viscosity index—key ASTM metrics that define how fast oil can move before freezing or thinning. In lab testing, oils with pour points near -60°F maintain fluid mobility through extended sub-zero storage, preventing starvation on the first pull of the day. In a snowmobile, that difference isn’t theory—it’s the gap between an engine that fires cleanly and one that protests every morning.

I still remember that day in the backcountry — minus twenty, maybe colder with the wind. We’d been riding hard since sunrise and stopped for a long lunch, sleds parked in a line, steaming like horses after a race. One guy in the group, proud of saving a few bucks, always said the same thing: “Oil is oil.” He ran conventional in everything — his pickup, his mower, and now his brand-new sled.

Two hours later, everyone hits the starters. You could hear each engine catch — whaap, whaap, whaap — clean, sharp, like they were eager to run again. Then came his. The starter dragged slow, the motor moaned, and you could almost feel the oil fighting the crank. The rest of us just looked over. Nobody said a word, but every face said the same thing — told you so.

That’s how most people learn what the spec sheet really means. Cold doesn’t care what label’s on the bottle; it just exposes what’s inside it.

For practical cold-weather prep, maintenance checklists, and snowmobile-safety guidance, the Minnesota Department of Natural Resources Snowmobiling Guide is one of the best neutral resources available.

Modern two-stroke engines don’t run like the ones most riders grew up with. Direct injection and computer-controlled oiling have cut the amount of lubricant that reaches the cylinder, even as RPM and cylinder pressure have climbed higher.

For example, a modern Rotax E-TEC can spin close to eight thousand revolutions a minute with exhaust-gas temperatures pushing twelve hundred degrees. That combination—less oil, more heat—means only the strongest formulations survive. A good two-stroke oil has to hold its film when injection rates drop and keep surfaces clean when temperatures spike.

At higher elevations, thinner air leans the fuel mixture even more, which means oil delivery and combustion temperatures shift upward — another reason thin, stable synthetics matter.

Thermally stable synthetics maintain composure at these extremes, resisting the carbon bonding that locks power valves and scorches piston crowns after repeated wide-open runs. That resistance comes from a high flash point—around 216°F in premium synthetics—which minimizes unburned residue and slows carbon crystallization at the exhaust port. The cleaner the burn, the freer the power valve movement, and the longer the piston coating stays intact. Anything less, and scuffing, ring stick, or power loss are inevitable.

For a deeper look at how exhaust power valves work and why deposit buildup limits performance, see this technical overview: How Power Valves Improve Two-Stroke Performance.

Lubricity under pressure defines how well an oil keeps metal surfaces separated when the film gets dangerously thin. In two-stroke engines, that moment comes during throttle bursts when injection drops but heat keeps rising. The ASTM D4863 test was built to measure that exact failure point — where friction climbs, torque falls, and scuffing begins.

A quality oil holds its film even when it’s running lean, sustaining stable lubrication above six hundred degrees Fahrenheit. In lab terms, that means minimal torque loss; in field terms, it means a sled that doesn’t seize when conditions go borderline-dry. The chemistry does the heavy lifting — strong base oils, surface-active additives, and a film that refuses to collapse under load.

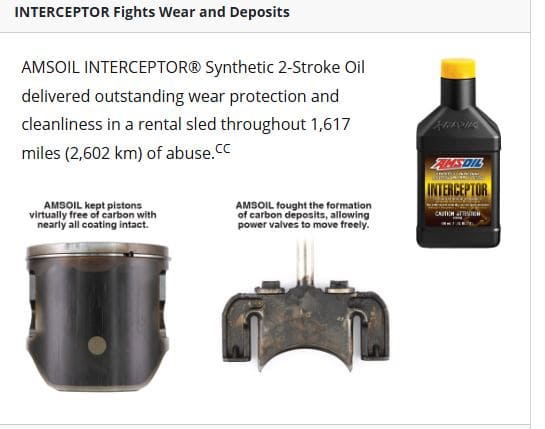

Cleanliness under fire is where most two-stroke oils fail. The ASTM D4857 test measures how well a lubricant keeps pistons, rings, and ports free of carbon and varnish during sustained high-temperature operation. When deposits form, rings stick, compression drops, and heat builds in all the wrong places.

A superior oil prevents that spiral by holding detergents and dispersants in balance. It keeps the crown, ring lands, and exhaust ports clean enough to breathe, even after hours of hard running. In real terms, it means steady power, smooth throttle response, and a piston that looks worked-in, not burned-out.

Proof in motion always comes after the lab work. On a clean test bench, numbers prove film strength and cleanliness, but in the field, the real verdict is how the engine sounds and feels after a full season. Low wear shows up as a consistent idle, crisp throttle response, and piston skirts that still carry their cross-hatch polish.

A well-balanced two-stroke oil does more than protect—it stays stable through heat cycles, leaves ports open, and keeps bearings from polishing themselves to death. When chemistry and application match, the engine runs quieter, temperatures stay lower, and teardown inspections read like confirmation instead of surprise. Extended-run testing backs this up: oils that preserve piston coating and cross-hatch integrity after a thousand-mile season prove their worth beyond any lab number.

Field endurance separates formulas built for show from those built for survival. Endurance oils typically show a viscosity index near 170 and pass JASO FD or ISO-L-EGD detergent standards, both requiring strict limits on piston deposits and ring sticking after multi-hour high-load runs. Those standards, not slogans, are what separate real field performers from shelf promises.

Modern blended fuels introduce another challenge — ethanol pulls moisture that can attack storage oils and alter film chemistry. Quality two-stroke synthetics counter it with better demulsifiers and corrosion inhibitors.

Oil compatibility matters more than riders think. Mixing different two-stroke oils can upset detergent balance and film chemistry, leading to deposit instability. Whenever changing brands or formulas, purge the system first—synthetic injection oils are engineered to run clean at ratios near 50 : 1, but only when given a pure start.

In the end, the rules never change — friction is honest, heat is relentless, and oil chemistry doesn’t care what you paid for it. The best two-stroke oils earn their reputation where it counts: out in the cold, under load, when there’s no margin for error.

If you ride long enough, you learn that maintenance isn’t about saving money; it’s about saving metal. Choose oil for its performance, not its price tag. The machines you depend on will tell you the truth one way or another — either in quiet reliability or in the sound of a dry crank at twenty below.

Out in the cold, there’s no debate — either the oil flows, or the engine quits.