Here’s the cold-start test that shows which oils protect fastest

Quick Take:

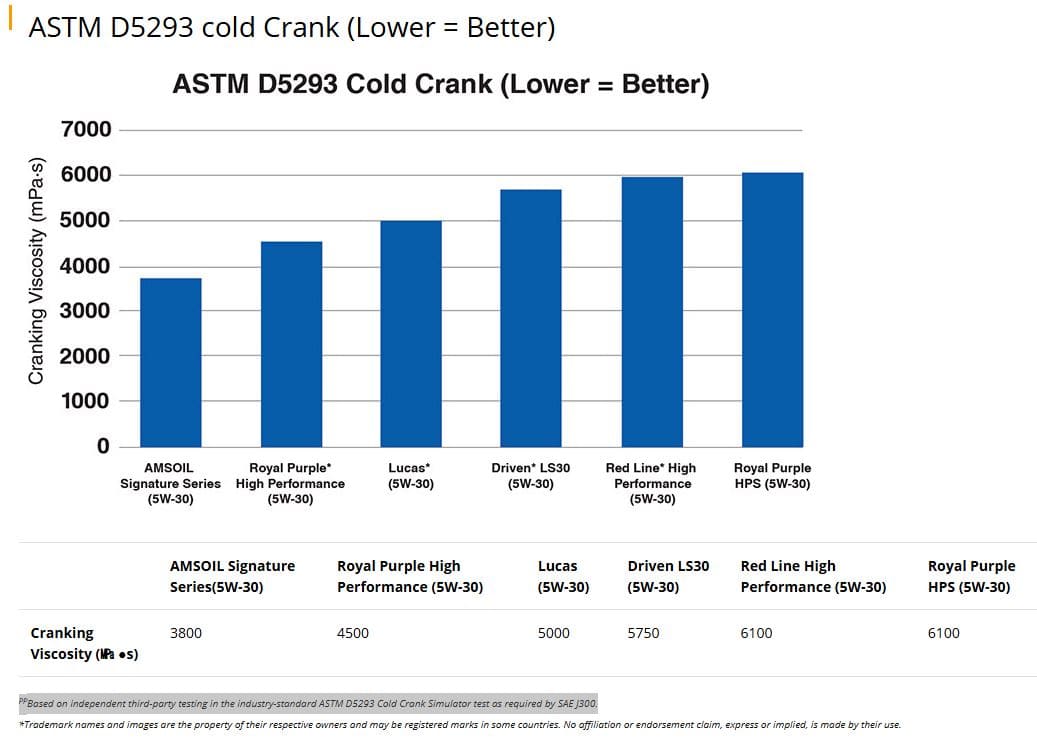

The ASTM D5293 Cold-Cranking Simulator measures how easily oil flows in extreme cold. Lower viscosity here means faster oil circulation, quicker startup protection, and less wear — especially important since up to 80% of engine wear happens during cold starts.

Cold Starts: The Silent Engine Killer

Picture pouring maple syrup straight from the fridge. It crawls. Your engine oil behaves the same way on a freezing morning. The longer it takes to move, the more unprotected metal grinds against metal — and that’s where the damage begins.

Studies have shown that up to 80% of total engine wear occurs during cold starts. Until oil pressure builds and forms a protective film, parts like bearings, rings, and cams are running almost dry. In subfreezing temperatures, that delay gets worse — unless your oil is designed to stay fluid when it’s cold.

The 10-Second Battle That Decides Engine Life

The ASTM D5293 Cold-Cranking Simulator (CCS) is the industry’s way of timing that syrup-like moment.

Here’s what it does:

- Chills the oil to extreme temperatures (–25 °C to –35 °C)

- Spins it in a high-shear device that mimics a starter motor under load

- Measures the resistance in centipoise (cP) — the lower the number, the easier the crank, the faster the oil moves

A lower cold-cranking viscosity means:

- Quicker circulation through critical parts

- Less metal-to-metal contact

- Reduced risk of startup scoring and wear

From Molecules to Motion: Why Base Oil Matters

Synthetic oils start with precision-engineered molecules of uniform size and shape, free from the waxes and contaminants found in conventional petroleum refining. This gives them inherent advantages:

- Faster cold flow at low temperatures

- Greater film strength under load

- Better thermal stability over time

Conventional oils, by comparison, have a mixed molecular “grain” that thickens more in the cold, delaying the moment of full protection.

Real-World Proof in the Lab

In independent ASTM D5293 testing, AMSOIL Signature Series 5W-30 recorded lower cold-cranking viscosity than competing oils, including Royal Purple 5W-30 — indicating faster oil flow and earlier startup protection in severe cold. This isn’t a sales pitch; it’s a measurable performance difference backed by standardized testing.

Additives: The Hidden Players in Cold Performance

Cold-start protection isn’t just about the base oil. The blend of viscosity index improvers, pour point depressants, and anti-wear additives determines how an oil behaves when temperatures drop.

- Tier 1 additives = Meets OEM minimums at lowest cost

- Tier 2 additives = Higher performance, better durability

- Tier 3 additives = Top performance, often used in specialty blends where cost is secondary to protection

Specialty blenders often choose Tier 3 chemistry, pairing it with top-grade synthetics for maximum cold-start readiness.

From the Field: How the D5293 Cuts Through the Noise

In the lubrication industry, cold-start performance is one of the clearest indicators of real-world protection — and one of the hardest for marketing to spin. The ASTM D5293 removes the guesswork by using a repeatable, standardized method to compare oils under identical conditions. No slogans, no subjective impressions — just numbers that tell you how quickly each oil can reach critical components when temperatures plunge.

FAQ

Q1: Does lower cold-crank viscosity mean the oil is too thin?

No. ASTM D5293 values still fall within SAE J300 limits for the grade. Lower viscosity simply means faster flow at startup, reducing wear risk before full oil pressure builds.

Q2: Is ASTM D5293 the same as real-world cranking?

Not exactly — it’s a controlled simulation that correlates with cold-start difficulty. Real conditions vary with battery strength, starter condition, and fuel quality, but D5293 remains a reliable predictor of cold-weather performance.

Further Technical Reading:

ASTM D5293 Cold-Cranking Simulator – Nevada Dept. of Agriculture