In the world of automobiles, fuel injection has revolutionized how we approach engine performance and emissions. Historically, car enthusiasts had to choose between horsepower and low emissions. Today, due to advancements in fuel injection technology, we can enjoy both. This post explores the evolution of fuel injection, the benefits and challenges of modern direct injection, and how managing fuel injector deposits with AMSOIL products can keep your engine running smoothly.

From Carburetion to Direct Injection

Carburetion: The Old School Approach

Older cars used carburetion, a method where fuel was directly dumped into the engine. This provided a rich fuel mixture but lacked precision. Cars with carburetors often had inconsistent fuel distribution, which could lead to inefficiencies and higher emissions.

Transition to Throttle Body Injection (TBI)

Throttle Body Injection (TBI) was the next step in fuel injection evolution. In TBI systems, fuel was injected over the throttle body, providing a richer mixture than carburetion. This method allowed for better fuel control but still washed the valves, leading to potential deposit formation.

Development of Multi-Port Injection

Multi-port injection systems placed injectors right above the valves, offering improved fuel control and leaner mixtures. This advancement reduced emissions and increased efficiency. However, it still wasn’t perfect and left room for improvement in fuel distribution.

Advancement to Direct Injection

Direct injection represents the pinnacle of fuel injection technology. In direct injection systems, fuel is injected directly into the cylinder, allowing for precise control over the fuel-air mixture. This method enhances engine performance and reduces emissions, but it comes with its own set of challenges.

Benefits of Direct Injection

Improved Fuel Efficiency

Direct injection improves fuel atomization, which leads to more efficient combustion. This efficiency translates to better fuel economy, saving you money at the pump.

Enhanced Engine Performance

By injecting fuel directly into the cylinder, direct injection systems can maximize power output. This improvement allows engines to deliver higher horsepower without sacrificing efficiency.

Lower Emissions

Direct injection allows for leaner fuel mixtures, which can significantly reduce harmful emissions. This is a key step in making modern engines more environmentally friendly.

Challenges with Direct Injection

Lean Fuel Mixtures

Direct injection systems operate with leaner fuel mixtures compared to previous methods. While this improves efficiency, it can also lead to problems like pre-ignition and knocking.

High Cylinder Pressures

Direct injection creates higher pressures within the cylinder. This increased pressure generates more heat, which can cause issues like increased wear and potential engine damage.

Heat-Induced Deposits

One significant drawback of direct injection is the formation of deposits. High heat levels can lead to deposit accumulation on piston crowns, ring lands, and injectors. These deposits affect spray patterns and reduce engine efficiency.

Managing Heat and Deposits

The Problem with Heat

Excessive heat in the engine can cause deposits to form. These deposits are problematic as they impair engine performance and efficiency.

Where Deposits Form

Deposits tend to form in several critical areas:

- Piston Crowns: Deposits on piston crowns can lead to pre-ignition and knocking.

- Ring Lands: Accumulation in ring lands can cause the rings to stick, leading to poor compression and increased oil consumption.

- Injectors: Deposits on injectors can disrupt fuel spray patterns, reducing combustion efficiency.

Impact on Engine Performance

Deposits negatively affect engine performance by impairing fuel atomization and combustion. This decreases the efficiency of the engine, leading to higher fuel consumption and emissions.

Introduction to Upper Cylinder Lubricant

Purpose of Upper Cylinder Lubricant

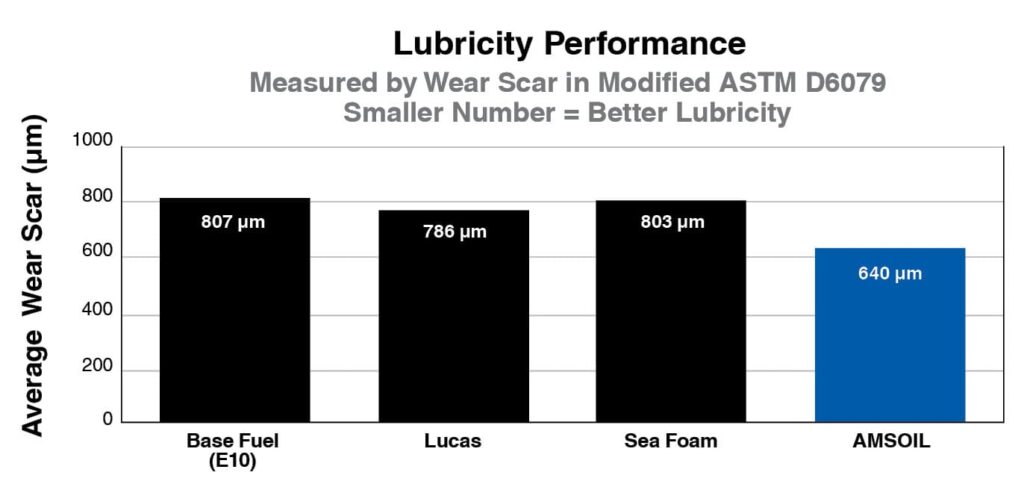

AMSOIL Upper Cylinder Lubricant is designed to combat the problems caused by heat and deposits. This powerful additive has potent detergency that helps to clean and protect your engine.

Usage Recommendations

For best results, add the upper cylinder lubricant to every tank of fuel. This continuous treatment ensures that deposits are consistently managed, and your engine remains protected from the harmful effects of heat.

Importance of Frequent Use

Regular use of the upper cylinder lubricant is crucial. Consistent application helps to maintain clean injectors and optimal spray patterns, ensuring your engine runs efficiently.

Advantages of Adding Upper Cylinder Lubricant

Easy Application

Adding the upper cylinder lubricant directly to the fuel tank is the easiest and most effective method. This approach avoids the need to handle high-pressure fuel system lines, making it a safe and straightforward process.

Safety Considerations

High-pressure fuel systems can be dangerous to handle. By adding the lubricant directly to the fuel tank, you avoid the risks associated with opening fuel lines.

Convenience and Effectiveness

Using the upper cylinder lubricant every time you fill up is convenient and ensures continuous protection. This routine helps prevent deposit buildup and maintains engine performance.

Benefits of AMSOIL Upper Cylinder Lubricant

Enhances Engine Performance

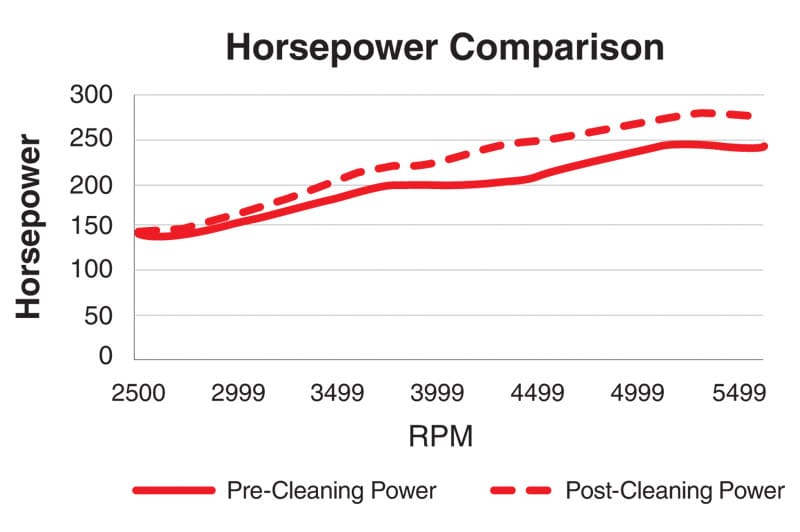

The upper cylinder lubricant helps keep injectors clean and functional. This maintenance allows for better fuel atomization and combustion, which enhances overall engine performance.

Reduces Deposit Formation

Potent detergents in the lubricant reduce and prevent deposit formation. This protection keeps your engine running smoothly and efficiently.

Protects Fuel System Components

Regular use of the upper cylinder lubricant extends the life of your fuel system components by preventing deposit-related wear and tear.

Recommended Practices for Vehicle Owners

Consistent Use of Additives

Make it a habit to add the upper cylinder lubricant to your fuel tank with every fill-up. Consistent use is key to maintaining a clean and efficient engine.

Monitoring Engine Performance

Regularly monitor your engine’s performance. Notice any changes in fuel economy or power output, which can indicate the need for further maintenance or adjustments.

Closing Remarks

Using additives like AMSOIL Upper Cylinder Lubricant is crucial for modern engines. These products help manage fuel injector deposits, enhance performance, and protect your engine from the harmful effects of heat. Make it a regular practice to use these additives and ensure your engine stays in top condition. For more details on AMSOIL products and their benefits, visit bestengineoilintheworld.com. The website offers comprehensive resources and support for maintaining your vehicle.