There’s a reason so many flat-tappet engines never make it to the mileage they should. It’s not bad parts or bad luck — it’s bad oil choices. The stuff lining most shelves today was built for emission-era engines with roller cams and catalytic converters, not for cam lobes that live and die by splash lubrication and zinc chemistry.

Old engines need more than nostalgia — they need chemistry that fights back. The right oil isn’t about brand loyalty or shiny bottles; it’s about molecules that can handle metal-to-metal pressure without folding. Zinc dialkyldithiophosphate (ZDDP) still does the heavy lifting, but modern synthetics give it the muscle it never had — purer base stocks, tighter film strength, cooler operation. Together, they bridge the gap between throwback hardware and modern chemistry.

So before you blame the cam grinder or the guy who set your lash, take a look at what’s in the crankcase. This isn’t nostalgia — it’s mechanics, refined. What follows isn’t a product pitch or a “top three” list — it’s a straight look at what actually keeps those old valvetrains alive when the film breaks and the load hits.

Flat-tappet camshafts operate under some of the most punishing lubrication conditions in any engine. The lifter and cam lobe slide directly against each other, creating a concentrated contact zone where surface pressures spike and temperatures rise fast. Unlike bearings or journals that enjoy steady oil pressure, these points rely on splash lubrication — a fleeting mist of oil that’s more guess than guarantee.

Under those conditions, boundary lubrication takes over. The oil film thins until only the additive chemistry stands between steel and failure. That’s where zinc dialkyldithiophosphate (ZDDP) earns its keep. When heat and load peak, ZDDP reacts with the metal surface to form a phosphate-glass film — a sacrificial barrier that absorbs friction and prevents welding. Without it, the cam lobes and lifters begin to score, scuff, and lose profile geometry. The result isn’t just wear; it’s lost valve lift, rough idle, and a slow fade in engine efficiency.

In simple terms: the flat-tappet system demands an oil that can survive in the gray zone — where hydrodynamic films collapse, and chemistry becomes the last line of defense.

High-ZDDP formulations exist for one reason — to survive where pressure never lets up. Flat-tappet cams, lifters, and rocker arms operate in constant metal-to-metal proximity, depending entirely on the oil’s additive chemistry once the hydrodynamic film gives out. In these regions, zinc and phosphorus compounds (ZDDP) form the critical shield that separates movement from destruction.

When temperature and load rise, ZDDP decomposes into a phosphate-based anti-wear film that adheres to steel surfaces. This film doesn’t eliminate friction; it controls it — sacrificing microscopic layers of its own structure instead of the metal underneath. That’s why oils engineered with elevated ZDDP levels perform reliably in vintage or high-performance engines. They provide the additional margin that standard API-certified oils, constrained by emission-era limits, can’t deliver.

The takeaway: higher ZDDP isn’t about excess — it’s about endurance. It keeps classic mechanical designs alive by ensuring that the oil, not the metal, takes the beating.

For deeper insight into whether older engines still need high-zinc protection, see this technical article on high-zinc motor oil.

Long-term protection in stored engines isn’t just about keeping oil in the sump — it’s about what that oil does when oxygen, moisture, and inactivity start working together. Even sealed engines breathe, pulling humid air through breather caps and seals as temperatures fluctuate. That moisture condenses on internal metal surfaces, forming the thin film of water that begins the corrosion cycle.

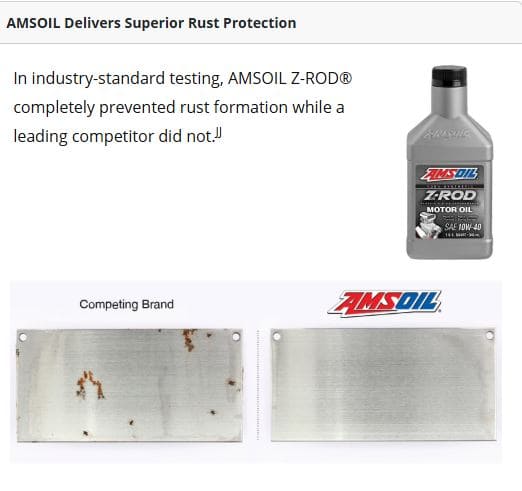

Rust inhibitors and corrosion suppressants are the unsung heroes in this environment. These compounds bond to metal surfaces, creating an invisible molecular barrier that resists oxidation. In laboratory verification, this protection is measured using the ASTM D1748 humidity cabinet test, where treated steel coupons are exposed to warm, saturated air. A passing oil prevents visible rust from forming across extended exposure periods — a clear indicator that its inhibitor package is holding the line.

For engines in seasonal storage, that chemistry is critical. Without it, surface rust blooms inside lifter bores, cam journals, and ring lands long before the next startup. Oils fortified for both performance and preservation ensure that when ignition returns, metal surfaces are still clean, smooth, and ready for film formation — not fighting through corrosion scars left by a damp winter.

Application range matters just as much as formulation. High-ZDDP oils like this one are intended for engines that predate the current emission-era categories — those built around API SL or earlier specifications. That cutoff exists for a reason: later standards (SM, SN, SP) drastically lowered zinc and phosphorus limits to protect catalytic converters, not camshafts.

In classic or performance engines, that trade-off doesn’t work. Flat-tappet designs, aggressive spring pressures, and wide bearing clearances all depend on additive chemistry unrestricted by modern emissions rules. That’s why these oils are offered in viscosities such as 10W-30, 10W-40, and 20W-50 — grades that maintain film strength under heat while still flowing at startup.

In short: use it where metallurgy and design still expect the older chemistry. It’s not about nostalgia; it’s about mechanical fit.

Compatibility is often misunderstood. While synthetic and conventional oils can technically mix without causing harm, the result is always a compromise. Additive systems are finely balanced — detergents, dispersants, and anti-wear agents are tuned to interact as a complete package. Blending two formulations dilutes that chemistry, shortening service life and reducing the margin of protection that specialized oils are built to provide.

Seal integrity is another concern in older engines, but modern synthetics are engineered with seal conditioners that maintain flexibility and prevent shrinkage or swelling. That’s why compatibility extends safely to vintage engines without risk of leaks or gasket degradation.

Aftermarket additives, however, are where trouble starts. Pour-in supplements often duplicate or unbalance the existing additive load, disrupting the film chemistry and sometimes neutralizing inhibitors entirely. If an oil is already formulated for high-ZDDP and rust protection, adding more isn’t enhancement — it’s interference.

Service life in older or modified engines is never one-size-fits-all. Every build runs a different combination of compression, fuel type, and heat load, so no blanket drain interval can account for those variables. That’s why responsibility for timing oil changes shifts from factory schedules to owner observation and analysis.

A practical upper limit for this type of oil is about 5,000 miles or two years, assuming the engine operates under normal seasonal use and sees occasional storage. Beyond that, oxidation, moisture accumulation, and additive depletion begin to erode protection — even if the oil still looks clean on the dipstick.

The smart move: treat time and temperature as equal enemies. Mileage matters, but so does sitting still. Oil ages chemically, not just mechanically, so service intervals should reflect both runtime and storage time.

ZDDP concentration is what separates ordinary oil from one capable of surviving a flat-tappet’s punishment. In most modern formulations, zinc and phosphorus hover near 800 ppm — just enough to meet emissions-driven categories, but not enough to sustain direct metal contact at the cam lobe.

Flat-tappet and high-load valvetrains demand higher film strength. That’s why most builders target 1,000 ppm or more of ZDDP once break-in is complete. At that level, the additive package can continually form and replenish its protective phosphate layer without exhausting itself under spring pressure and heat.

In premium formulations, zinc typically measures around 1,400 ppm, with phosphorus near 1,300 ppm. Those concentrations aren’t arbitrary — they reflect the point where chemical protection outweighs the risk of catalyst fouling while still giving classic and high-compression engines the sacrificial film they were designed to run on.

Every spec tells a story if you know what to look for. Viscosity at 100 °C — typically in the 12-to-20 cSt range for performance-grade 10W-30 through 20W-50 — shows how well an oil holds its film once the engine’s at temperature. Builders watch this number to judge whether the oil will maintain pressure and separation at full load. Drop to 40 °C, and you see how the same formulation behaves at startup — a clue to cold-flow behavior that can make or break wear patterns in the first thirty seconds of firing.

Viscosity index near or above 150 is a sign of stability across heat cycles. Oils in that class tend to resist thinning in summer heat yet still flow in a cold garage. Flash and fire points above roughly 450 °F suggest a strong synthetic base stock — the kind less prone to vapor loss or deposit formation under extended high-RPM operation.

Pour-point data in the minus-30s to minus-40s indicate readiness for off-season cranking, while Noack volatility in the 3–5 percent band tells you evaporation and oil consumption will stay under control. Many custom builders also pay attention to high-temperature, high-shear viscosity (around 3 – 6 cP at 150 °C) because that’s where film strength meets real-world bearing pressure.

In lab discussions, Four-Ball wear scars near 0.33 mm and a base number around 9 are often cited as indicators of a balanced additive system — one strong enough to fight wear and corrosion without turning the oil into a detergent bath.

Put simply: when you’re evaluating a high-zinc oil for a classic or performance engine, look for specs in these ranges. They’re the fingerprints of a formulation designed for longevity, not marketing. Some premium synthetics on the market, including ZDDP-rich blends used in classic-engine circles, consistently hit those marks — which is why experienced builders keep them on the short list.

For more perspective on how wear and oil chemistry connect, see this short guide from MotorTrend: Worn-Down Engines.

Here’s the thing — age doesn’t mean antique thinking. Just because your classic or muscle car rolled off the line when Zeppelin was still touring doesn’t mean it has to run on the same sludge your granddad poured from a metal can. Engines evolve, chemistry evolves — and the smartest builders today know that the sweet spot isn’t nostalgia or novelty, it’s the mix of both.

That’s where zinc meets synthetics. ZDDP gives you that old-school sacrificial shield — the proven chemistry that protects flat-tappets and cam lobes when pressure peaks. Synthetic base oils bring the modern half of the equation: pure molecular structure, cooler running temps, and a film that refuses to shear down when the revs climb. Together, they don’t cancel each other out — they multiply the protection.

Conventional oil, meanwhile, is geology with a hangover. It’s cracked, refined, filtered — but never truly clean. You can strip out the worst of the sulfur and nickel, but you can’t change the fact that its molecules are a mixed bag of shapes and sizes. That inconsistency is what causes varnish, sludge, and volatility. It’s also why that same old 10W-40 smells like it’s burning off faster than your patience.

So yeah — your car might be vintage, but your lubrication doesn’t have to be. Zinc gave the classics their backbone. Synthetics give them a second act. The chemistry caught up. The only real question is whether you have.

Does Z rod oil contain “fast acting zinc “?

Yes, Z Rod Engine Oil utilizes “fast-acting” zinc.