Ever wondered why the function of motor oil is so crucial for your car’s engine? It’s not just about reducing friction; motor oil has several essential roles that keep your engine running smoothly. From cooling engine parts and preventing corrosion to sealing tiny gaps between components, understanding these functions can make all the difference. In this post, we’ll explore the different types of lubrication, such as boundary, hydrodynamic, and elastohydrodynamic, and identify which engine tasks rely heavily on proper lubrication. Don’t miss out on learning why choosing the right motor oil is vital for your engine’s health.

1. Improve Engine Efficiency Using Synthetic Oil for Cooling

Reducing friction in machinery diminishes the heat generated by moving parts, contributing to a cooler operating environment for the equipment. This is crucial for maintaining optimal performance and preventing overheating issues that could lead to mechanical failure. Additionally, lubricants play a vital role by absorbing heat from the contact areas and transporting it to designated safe zones, such as the oil sump, where the heat can be effectively dispersed. The efficiency of heat transfer often hinges on the viscosity of the base oil. Typically, thinner oils exhibit superior heat transfer capabilities due to their lower resistance to flow, which allows them to carry heat away more efficiently. This characteristic makes them particularly suitable for applications requiring rapid and effective cooling of components. Conversely, while thicker oils may provide better lubrication in certain scenarios, their higher viscosity can impede heat transfer, thus necessitating a careful balance based on the specific requirements of the machinery in question.

2. Minimize Friction and Reduce Wear with Synthetic Oil

Motor oil’s primary function is to reduce friction and wear between moving parts within an engine. It accomplishes this by forming a thin, protective layer over metal surfaces, significantly lowering the friction encountered during operation. This reduction in friction is crucial because it leads to less heat generation and diminished wear on critical components such as engine bearings. By minimizing wear and heat, motor oil not only extends the lifespan of engine parts but also enhances overall engine efficiency and performance. Furthermore, efficient lubrication helps in maintaining optimal engine temperature, which prevents overheating and subsequent damage to internal components.

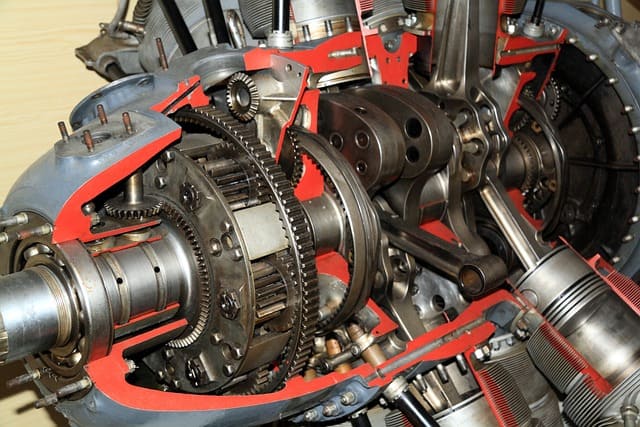

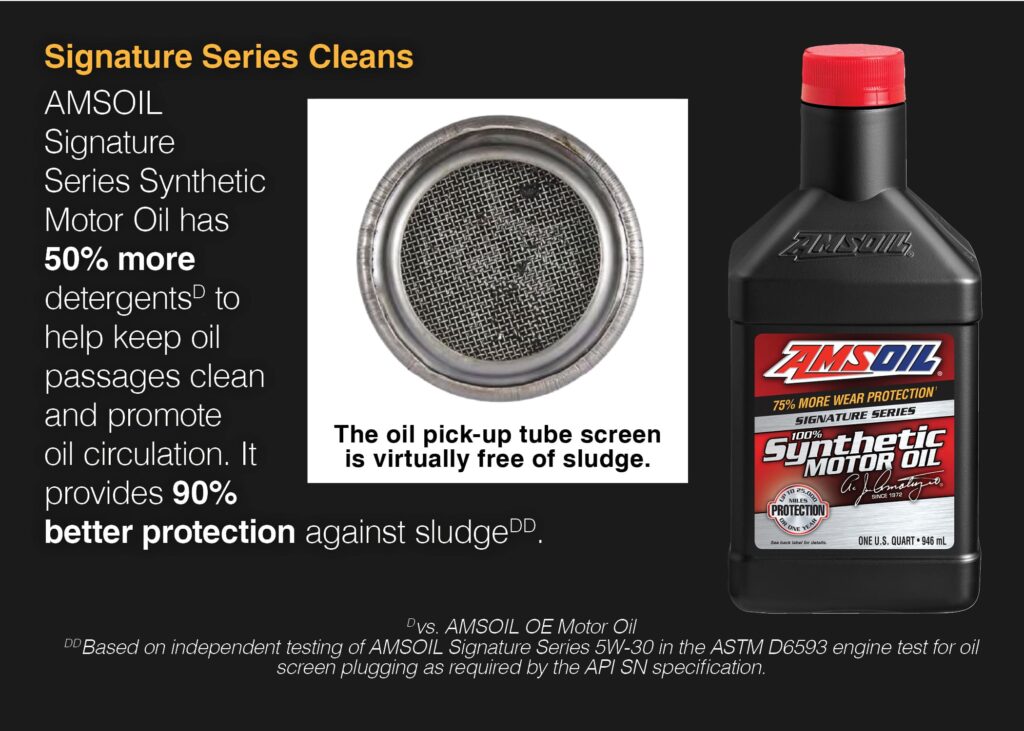

3. Cleaner Engines Start with Synthetic Oil

Motor oil has a crucial role in keeping engine components clean. It does this by holding contaminants within the oil itself, stopping them from sticking to engine parts. Base oils, which come with different levels of solvency, can dissolve various substances, helping to keep the engine clean. But solvency alone isn’t enough; detergents and dispersants are also key players. Detergents are special additives that prevent contaminants from clinging to engine parts, especially those exposed to high temperatures like pistons and piston rings. Dispersants, on the other hand, keep these particles suspended in the oil, working in a way similar to solvents. This dual action keeps the oil clean and greatly reduces sludge formation, which can harm engine performance. Without these additives, debris and sludge would build up, leading to increased wear and potential engine failure. The right balance of base oils, detergents, and dispersants ensures that the oil not only lubricates but also cleans and protects the engine over time.

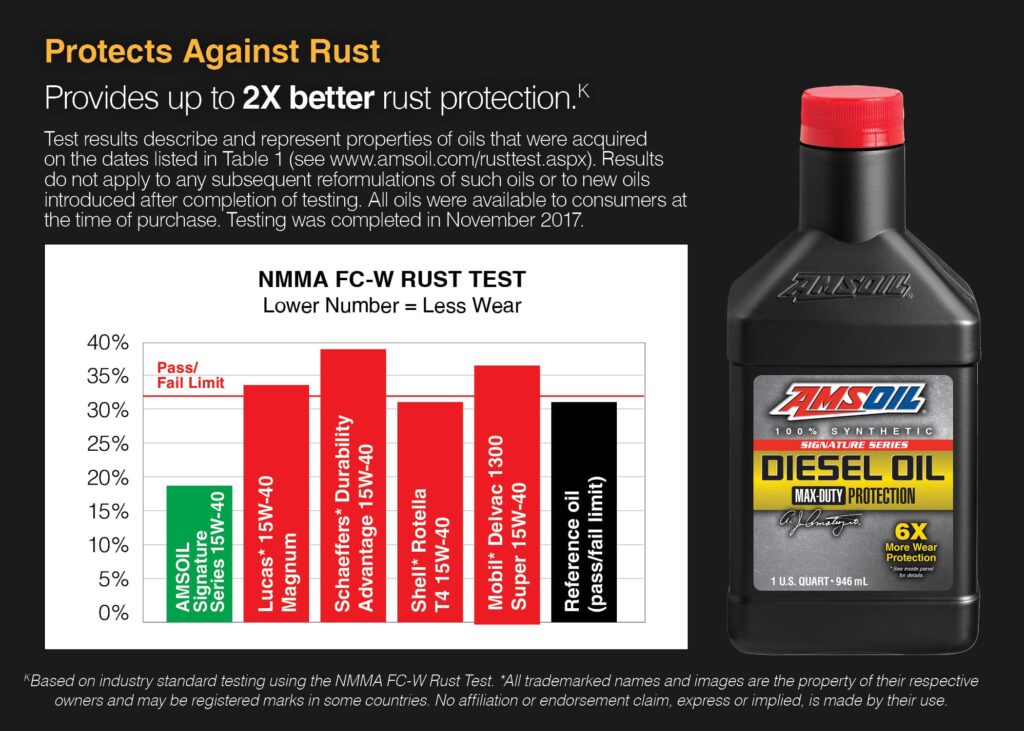

4. Corrosion Prevention with Synthetic Engine Oil

For a lubricant to be effective, it must prevent or reduce the corrosion of internal parts. This can be accomplished by the oil neutralizing corrosive substances or by forming a protective layer between the components and the corrosive elements. The neutralization process involves chemical reactions that render the corrosive agents harmless. In contrast, the protective layer acts as a physical barrier, preventing direct contact between the metal parts and the corrosive elements.

However, if rust or corrosion does occur, the resulting particles can break off and contaminate the oil. This contaminated oil then circulates through the system, potentially damaging metal bearings and other crucial parts. Over time, the accumulation of these abrasive particles can cause significant wear and tear, leading to the inevitable failure of components, necessitating repair or replacement. This emphasizes the importance of using high-quality lubricants that offer robust protection against corrosion to maintain the longevity and efficiency of mechanical systems.

5. Synthetic Motor Oil: Key to Superior Energy Transfer

Because lubricants can’t be compressed, they’re optimal for transferring energy, especially in hydraulic systems and valve lifters in car engines. In the automotive sector, numerous modern engines with variable-valve-timing systems utilize motor oil as a hydraulic fluid to manage different engine components. Motor oil plays a dual role, serving both as a lubricant and a hydraulic fluid, which highlights its critical function. Consequently, it’s vital that the oil remains clean and maintains its viscosity to perform effectively.

If the oil gets contaminated or its quality degrades, it can result in poor energy transfer and potentially damage engine parts. For instance, dirty oil can clog small passages in hydraulic lifters, affecting engine performance. Low-viscosity oil might not provide adequate cushioning, increasing wear and tear. These issues underscore the necessity for regular oil changes and the use of high-quality motor oils. Regular maintenance ensures that the oil can continue to lubricate and transfer energy efficiently, safeguarding the engine’s longevity and performance.

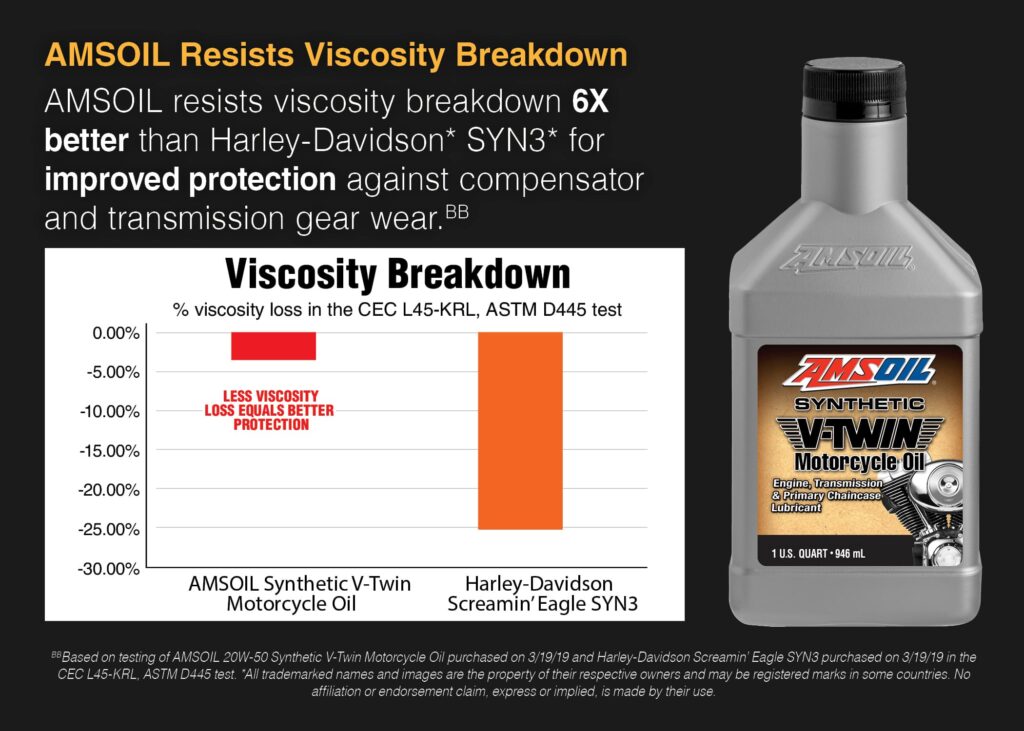

6. Synthetic Engine Oil and Shock Mitigation

A primary function of motor oil is to mitigate the impact of mechanical shocks. By forming a robust oil film, motor oil can withstand breaking and effectively disperse energy surges over a broader area. This distribution of force reduces stress on individual components, thereby minimizing wear and tear and ultimately extending the lifespan of these parts. For instance, consider a motorcycle transmission. If the oil becomes too thin and fails to create a durable film on the gears, it leads to noisy and rough gear shifts. Such deterioration in performance is undesirable for any rider, as it not only affects the smoothness of operation but also signals potential damage to the transmission system. Additionally, maintaining the oil’s viscosity is crucial for preserving the integrity of the mechanical components, ensuring they operate efficiently and reliably over time. Without a consistent and strong oil film, the machinery is subjected to increased friction and stress, which accelerates degradation and reduces overall performance. Hence, regular oil maintenance is essential for optimal functionality and longevity of mechanical systems.

7. Superior Sealing with Synthetic Motor Oil

Motor oil serves as an essential sealant in various engine parts, particularly within the combustion chamber. It ensures the piston rings are tightly pressed against the cylinder wall, preventing hot exhaust gases from infiltrating the oil supply. This tight seal is vital for maintaining proper engine compression, which directly impacts the engine’s efficiency and performance. Without this seal, the integrity of the combustion process could be compromised, leading to decreased power output and increased wear on engine components.

Furthermore, the seal keeps oil from seeping into the combustion chamber, thereby reducing oil consumption and preventing the formation of harmful deposits on the spark plugs and valves. An effective seal not only preserves the integrity of engine components but also supports cleaner combustion processes. Cleaner combustion results in fewer emissions, contributing to better environmental outcomes and compliance with emission regulations.

In terms of fuel economy, an engine with a proper oil seal operates more efficiently, converting more of the fuel’s energy into useful work. Some may argue that alternative methods, such as advanced gasket materials or improved manufacturing tolerances, can achieve similar results. However, these alternatives often lack the multi-faceted benefits provided by motor oil. The role of motor oil in sealing remains a proven and indispensable aspect of engine maintenance, ensuring longevity and reliability of the engine while promoting optimal performance and reduced environmental impact.

In conclusion, understanding the function of motor oil extends beyond simply reducing friction. By exploring why motor oil is used, the various types of lubrication, and the specific engine tasks dependent on proper lubrication, you gain a comprehensive view of its essential role. From cooling engine parts to preventing corrosion, motor oil proves its worth time and again. Knowing these functions empowers you to make informed decisions on engine maintenance and oil selection.