Quick Take

- Purpose of the Test: Measures a motor oil’s ability to prevent wear on camshaft lobes under controlled conditions.

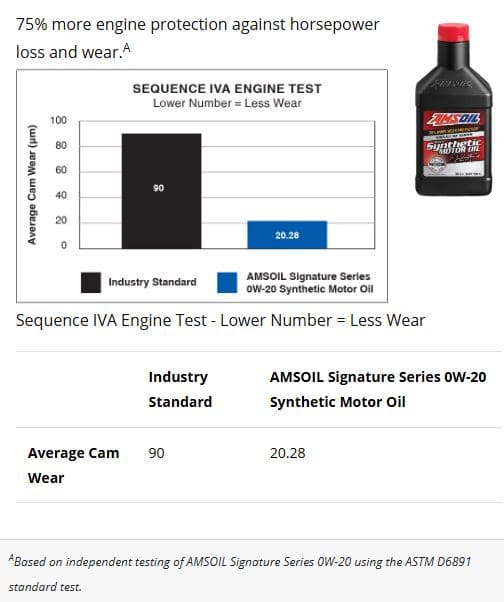

- Key Metric: Average cam wear in micrometers — lower numbers indicate better wear protection.

- Industry Benchmark: ~90 µm average cam wear.

Example Result: One oil in ASTM D6891 testing recorded 20.28 µm, showing substantially less wear than the industry standard.

What the Sequence IVA Engine Test Measures in Camshaft Wear

The Sequence IVA Engine Test (ASTM D6891) is a standardized laboratory procedure used to evaluate a motor oil’s ability to protect sliding surfaces from wear, especially in low-temperature, start–stop conditions.

How It Works:

- Engine Used: 2.3L Nissan KA24E inline four-cylinder.

- Operating Conditions: Low-load, low-speed cycling to simulate extended idling and stop-and-go driving — scenarios where the oil film is thinnest and wear risk is high.

- Duration: 100 hours of controlled operation.

- Measurement: After the test, the camshaft lobes are measured for material loss. The average wear depth in micrometers is the final score.

Why Engine Wear Data Matters for Real-World Driving

The Sequence IVA focuses on boundary lubrication — when the oil film is too thin to fully separate metal surfaces, and anti-wear additives take the lead role in protection.

Think of it like a county fair baking contest:

- Everyone uses flour, sugar, and eggs (base oils and additive basics).

- But the winning recipe comes from the baker who uses the freshest ingredients and the most precise technique — in oil terms, this means premium anti-wear chemistry such as high-purity molybdenum compounds, often combined with carefully limited amounts of ZDDP or other modern ashless additives to meet today’s emissions and durability standards.

A low wear number in this test means the oil is better equipped to handle the high-friction, low-speed contacts that occur thousands of times in every short trip, traffic jam, or cold start.

Interpreting Camshaft Wear Results from the Sequence IVA Test

- Industry Standard: About 90 µm cam wear is considered acceptable for API SN category oils.

- Example Performance: Independent ASTM D6891 testing of AMSOIL Signature Series 0W-20 Synthetic Motor Oil recorded just 20.28 µm average cam wear — roughly 75% less wear than the standard.

- Real-World Takeaway: Oils with significantly lower wear values help preserve horsepower over time by minimizing material loss on critical valvetrain components.

Further Reference: For a detailed breakdown of how this test is conducted and interpreted in the field, see the Sequence IVA discussion in AMSOIL’s technical blog.

Additive Chemistry and Its Role in Reducing Camshaft Wear

In the lubrication business, many well-known brands meet the API minimums with Tier 1 additive packages — sufficient for warranty compliance, but not engineered for extended wear resistance. Specialty blenders willing to invest in Tier 3 additive chemistry can produce oils that excel in demanding tests like Sequence IVA.

From decades in the B2B lubricant field, I’ve seen that the difference is rarely visible at the start — it’s measured in engine life years later. The Sequence IVA gives us a controlled way to see that difference before the miles add up.

FAQs

1. Does a good Sequence IVA score guarantee better engine life?

Not by itself. This test measures one specific wear mechanism — cam lobe wear in low-speed, stop-and-go conditions. Engine life also depends on other factors like deposit control, oxidation resistance, and viscosity stability, each evaluated by different ASTM tests.

2. Why is the test run at low speeds instead of high RPM?

Because high-RPM operation generates a thicker hydrodynamic oil film, which naturally reduces wear. The Sequence IVA is designed to challenge the oil’s boundary lubrication capability — the toughest condition for anti-wear chemistry to protect against metal-to-metal contact.

Reference: